We offer TSR grades of Solid Rubber. TSR is “Technically Specified Rubber” sometimes referred to as Block Rubber or Crumb rubber. It can be produced from both natural rubber field latex and field coagulum (cuplump) or a blend of both. TSR Rubbers are graded according to precise technical parameters such as content of Dirt, Ash, Nitrogen, Volatile Matter and its properties such as Wallace Plasticity (PO) and Plasticity Retention Index (PRI). It has good processing characteristics and physical properties.

Natural rubber process

ADDITIONAL INFORMATION

1. DEFINITIONS of SVR CV60, CV50

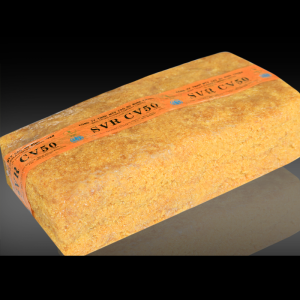

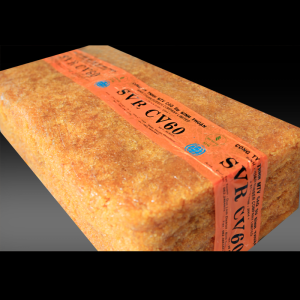

Technical Natural Rubber SVR CV is a rubber product line with stable viscosity. Two types of SVR CV rubber mainly include

SVR CV50

SVR CV60.

The rubber tree variety and the year of planting have a great impact on the quality of the product

In the developed rubber producing countries, in the production process, people are always equipped with main measuring and testing equipment, for example: 10 & 20 latex production is equipped with a plasticity meter, CV rubber is a machine. Viscosity measurement (you can still use a plasticity gauge to save money).

The control of the production process by measuring instruments for timely correction is very important to give the manufacturer the means to achieve his production goals by testing.

2. APPLICATIONS OF SVR CV RUBBER

Because CV (constant viscosity) rubber has the characteristic property of constant viscosity and flexibility, it is preferred by manufacturers. Flexibility is very convenient in the rolling process (such as low energy, synthesis, etc.) The combination of substances in a good mixture, high adhesion) will create a good and uniform product.

This type of rubber is used to make elastic bands, glue, tire sidewalls, table tennis rackets …

3. HIGHLIGHTS SVR CV60, CV50

Stable viscosity

The flexibility and adhesion have confirmed this rubber to thrive in the domestic market as well as the world.

4. QUALITY STANDARDS OF SVR CV50 SVR CV 60 . RUBBER

- Contaminant content retained on 45m sieve, % m/m, not more than: 0.02

- Ash content, % m/m, not more than: 0.40

- Nitrogen content, % m/m, not more than: 0.60

- Volatile matter content, % m/m, not more than: 0.60

- End ductility ( Po ), not less than: –

- Plasticity retention index (PRI), not less than: 60

- Lovibond color index, single, no more than :-

- Viscosity Mooney ML ( 1′ + 4′ ) 100oC: 60 ± 5 or 50±5

- PRODUCTION PROCESS OF RUBBER SVR CV OF NAM DAT T COMPANY

Depending on the specific requirements of each customer, SVR CV rubber products will be mixed to meet the requirements of the customer.